Shaping Rubber . this process involves shaping rubber materials, which can be either natural or synthetic rubber (elastomers). rubber molding is the process of shaping rubber or elastomer into a desired shape or form. the process of taking raw rubber and turning it into a shape or product is called rubber molding. The mold is then closed, applying pressure and heat to the rubber. rubber injection molding works by heating the rubber material and exerting intense pressure to inject the melted rubber. The raw material, often in the form of pellets, granules or powder, is placed into a heated chamber known as an injection barrel. in this discourse, we delve into the intricacies of these three distinct rubber molding methods, exploring their.

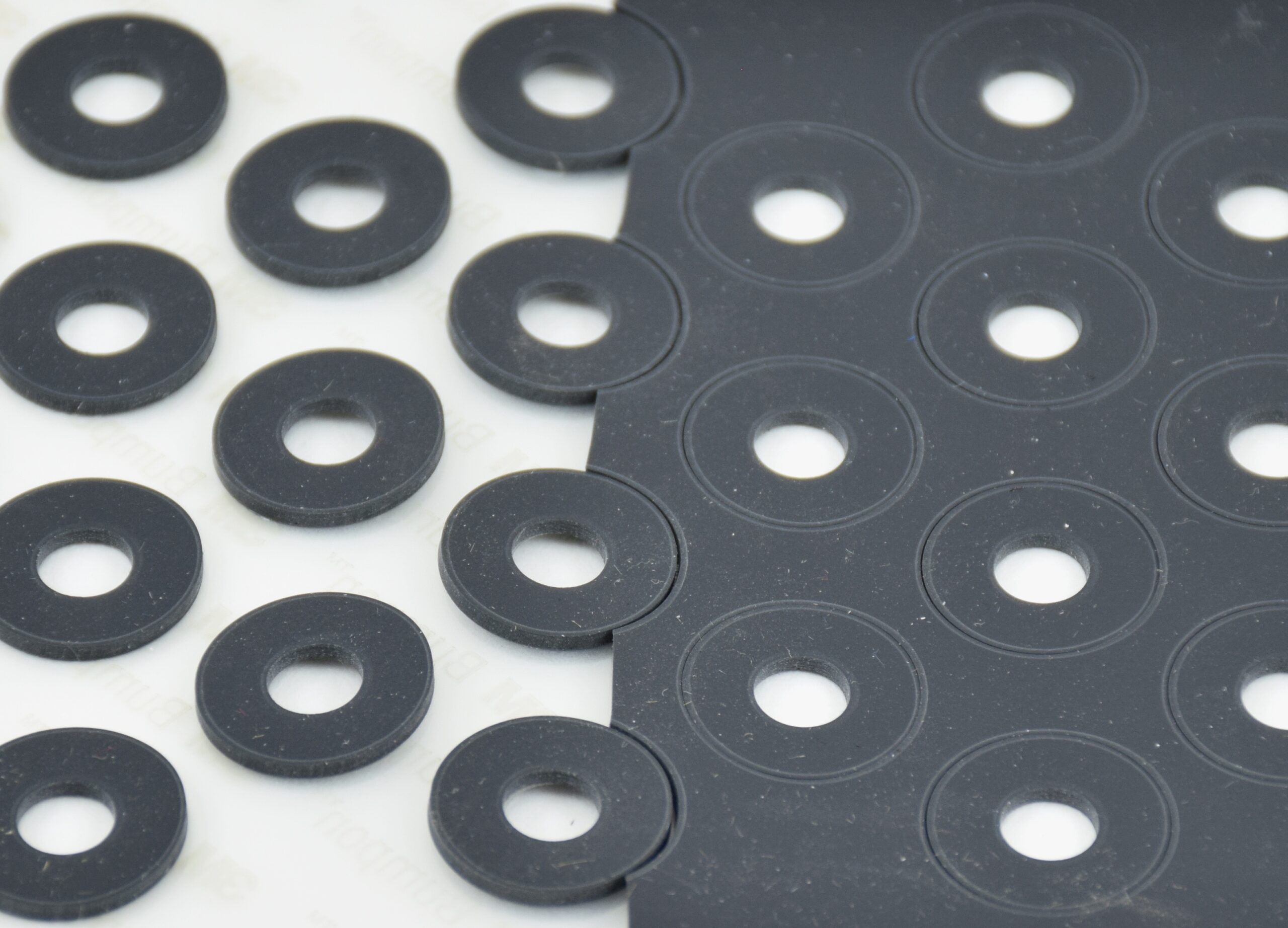

from americanflexible.com

The raw material, often in the form of pellets, granules or powder, is placed into a heated chamber known as an injection barrel. this process involves shaping rubber materials, which can be either natural or synthetic rubber (elastomers). the process of taking raw rubber and turning it into a shape or product is called rubber molding. The mold is then closed, applying pressure and heat to the rubber. rubber injection molding works by heating the rubber material and exerting intense pressure to inject the melted rubber. in this discourse, we delve into the intricacies of these three distinct rubber molding methods, exploring their. rubber molding is the process of shaping rubber or elastomer into a desired shape or form.

Custom Solid Rubber Products American Flexible Products

Shaping Rubber this process involves shaping rubber materials, which can be either natural or synthetic rubber (elastomers). this process involves shaping rubber materials, which can be either natural or synthetic rubber (elastomers). The mold is then closed, applying pressure and heat to the rubber. rubber molding is the process of shaping rubber or elastomer into a desired shape or form. rubber injection molding works by heating the rubber material and exerting intense pressure to inject the melted rubber. The raw material, often in the form of pellets, granules or powder, is placed into a heated chamber known as an injection barrel. the process of taking raw rubber and turning it into a shape or product is called rubber molding. in this discourse, we delve into the intricacies of these three distinct rubber molding methods, exploring their.

From shopee.ph

5Pcs/Set Yoga Fitness Resistance Shaping Rubber Bands/Workout Indoor Shaping Rubber this process involves shaping rubber materials, which can be either natural or synthetic rubber (elastomers). rubber molding is the process of shaping rubber or elastomer into a desired shape or form. The raw material, often in the form of pellets, granules or powder, is placed into a heated chamber known as an injection barrel. The mold is then. Shaping Rubber.

From www.amazon.co.uk

BOLAWOO77 Women S Rubber Corset Elastic Stretch Belly Body Shaping Shaping Rubber The mold is then closed, applying pressure and heat to the rubber. rubber molding is the process of shaping rubber or elastomer into a desired shape or form. rubber injection molding works by heating the rubber material and exerting intense pressure to inject the melted rubber. in this discourse, we delve into the intricacies of these three. Shaping Rubber.

From www.farfetch.com

SPANX fullcoverage Shaping Thong Farfetch Shaping Rubber The raw material, often in the form of pellets, granules or powder, is placed into a heated chamber known as an injection barrel. the process of taking raw rubber and turning it into a shape or product is called rubber molding. in this discourse, we delve into the intricacies of these three distinct rubber molding methods, exploring their.. Shaping Rubber.

From www.youtube.com

What is rubber transfer molding? YouTube Shaping Rubber the process of taking raw rubber and turning it into a shape or product is called rubber molding. rubber injection molding works by heating the rubber material and exerting intense pressure to inject the melted rubber. in this discourse, we delve into the intricacies of these three distinct rubber molding methods, exploring their. this process involves. Shaping Rubber.

From www.slideshare.net

Rubber processing technology Shaping Rubber rubber injection molding works by heating the rubber material and exerting intense pressure to inject the melted rubber. The mold is then closed, applying pressure and heat to the rubber. rubber molding is the process of shaping rubber or elastomer into a desired shape or form. this process involves shaping rubber materials, which can be either natural. Shaping Rubber.

From www.iqsdirectory.com

Rubber Bushings Types, Uses, Manufacturing, and Materials Shaping Rubber in this discourse, we delve into the intricacies of these three distinct rubber molding methods, exploring their. this process involves shaping rubber materials, which can be either natural or synthetic rubber (elastomers). the process of taking raw rubber and turning it into a shape or product is called rubber molding. rubber injection molding works by heating. Shaping Rubber.

From www.alibaba.com

Automatical Rubber Sealing Washer Vulcanizing Machine/rubber Mat Making Shaping Rubber The mold is then closed, applying pressure and heat to the rubber. in this discourse, we delve into the intricacies of these three distinct rubber molding methods, exploring their. rubber injection molding works by heating the rubber material and exerting intense pressure to inject the melted rubber. the process of taking raw rubber and turning it into. Shaping Rubber.

From www.youtube.com

What is rubber injection molding? YouTube Shaping Rubber in this discourse, we delve into the intricacies of these three distinct rubber molding methods, exploring their. rubber injection molding works by heating the rubber material and exerting intense pressure to inject the melted rubber. this process involves shaping rubber materials, which can be either natural or synthetic rubber (elastomers). The mold is then closed, applying pressure. Shaping Rubber.

From www.jarir.com

Artmate Rubber Pens, for Shaping General Craft Tool Jarir Bookstore Shaping Rubber The raw material, often in the form of pellets, granules or powder, is placed into a heated chamber known as an injection barrel. in this discourse, we delve into the intricacies of these three distinct rubber molding methods, exploring their. the process of taking raw rubber and turning it into a shape or product is called rubber molding.. Shaping Rubber.

From www.polymax.in

Rubber Moulding Supplies Custom Rubber Moulding Polymax India Shaping Rubber the process of taking raw rubber and turning it into a shape or product is called rubber molding. rubber injection molding works by heating the rubber material and exerting intense pressure to inject the melted rubber. The mold is then closed, applying pressure and heat to the rubber. The raw material, often in the form of pellets, granules. Shaping Rubber.

From www.dhgate.com

2020 Body Shaping Body Rubber Belt Unisex Xtreme Power Belt Hot Shaping Rubber this process involves shaping rubber materials, which can be either natural or synthetic rubber (elastomers). rubber injection molding works by heating the rubber material and exerting intense pressure to inject the melted rubber. The raw material, often in the form of pellets, granules or powder, is placed into a heated chamber known as an injection barrel. the. Shaping Rubber.

From www.walmart.com

QILIN 5Pcs Yoga Elastic Bands Flexible Vivid Color Wearresistant Shaping Rubber the process of taking raw rubber and turning it into a shape or product is called rubber molding. rubber injection molding works by heating the rubber material and exerting intense pressure to inject the melted rubber. The mold is then closed, applying pressure and heat to the rubber. rubber molding is the process of shaping rubber or. Shaping Rubber.

From www.rpmrubberparts.com

3 Types of Rubber Injection Moulding RPM Rubber Parts Shaping Rubber rubber molding is the process of shaping rubber or elastomer into a desired shape or form. in this discourse, we delve into the intricacies of these three distinct rubber molding methods, exploring their. the process of taking raw rubber and turning it into a shape or product is called rubber molding. The raw material, often in the. Shaping Rubber.

From www.rpmrubberparts.com

FAQs About Rubber Compression Molding Shaping Rubber The mold is then closed, applying pressure and heat to the rubber. rubber molding is the process of shaping rubber or elastomer into a desired shape or form. The raw material, often in the form of pellets, granules or powder, is placed into a heated chamber known as an injection barrel. in this discourse, we delve into the. Shaping Rubber.

From shopee.com.my

TikTok Gorilla Sand Soft Shaping Rubber Toys Pinch Fun Shaping Rubber in this discourse, we delve into the intricacies of these three distinct rubber molding methods, exploring their. rubber injection molding works by heating the rubber material and exerting intense pressure to inject the melted rubber. the process of taking raw rubber and turning it into a shape or product is called rubber molding. this process involves. Shaping Rubber.

From www.bruckmanrubber.com

Transfer Molding Bruckman Rubber Co. Shaping Rubber The mold is then closed, applying pressure and heat to the rubber. the process of taking raw rubber and turning it into a shape or product is called rubber molding. in this discourse, we delve into the intricacies of these three distinct rubber molding methods, exploring their. rubber molding is the process of shaping rubber or elastomer. Shaping Rubber.

From americanflexible.com

Custom Solid Rubber Products American Flexible Products Shaping Rubber The raw material, often in the form of pellets, granules or powder, is placed into a heated chamber known as an injection barrel. rubber molding is the process of shaping rubber or elastomer into a desired shape or form. The mold is then closed, applying pressure and heat to the rubber. in this discourse, we delve into the. Shaping Rubber.

From www.researchgate.net

Different manufacturing processes (a) milling process [12], (b Shaping Rubber rubber injection molding works by heating the rubber material and exerting intense pressure to inject the melted rubber. The mold is then closed, applying pressure and heat to the rubber. in this discourse, we delve into the intricacies of these three distinct rubber molding methods, exploring their. the process of taking raw rubber and turning it into. Shaping Rubber.